Well Integrity

Giving you the full picture of your well’s performance

Well Integrity

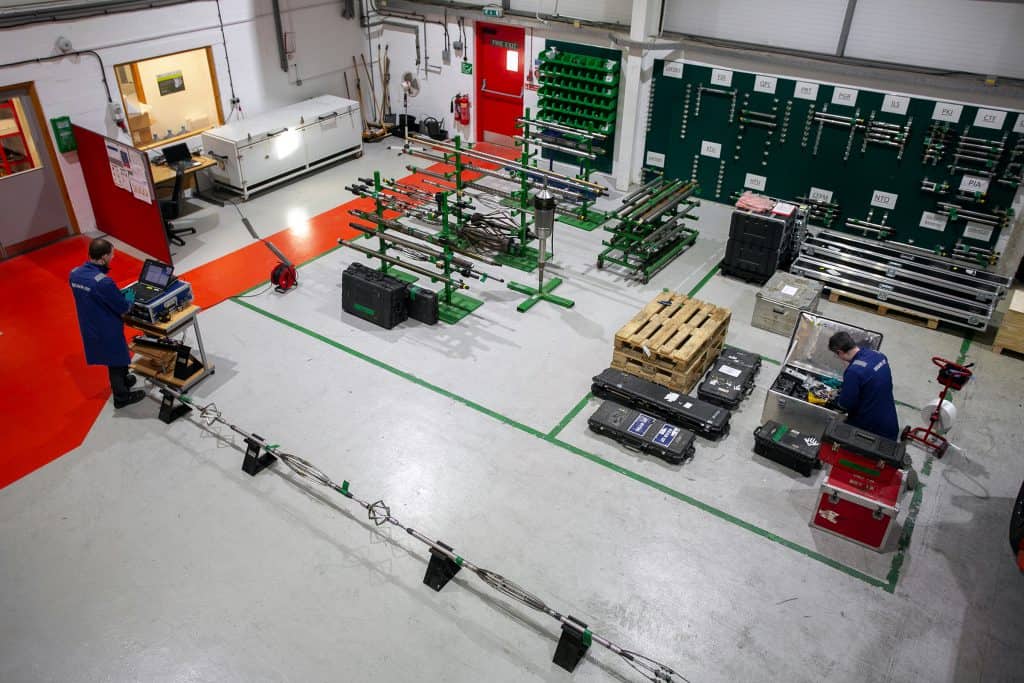

We are experts in well integrity evaluation. For 30 years we’ve been delivering solutions that help operators and service partners overcome their well challenges all over the world.

Well integrity evaluation means getting the full picture of your well’s barrier performance. It’s about understanding the structural integrity of your tubing, casing, liners and cement. Ultimately, this helps you manage risk, extend operating life and optimise the management of your wells across their lifecycle.

READ offers a range of specialist well integrity services, enhanced by value-adding technologies, for accurately identifying and quantifying damage and deformation, holes, leaks, corrosion and scale build-up, deployable on electric wireline, slickline or coiled tubing in memory and real-time.

Our solutions are tailored to your individual equipment and operations. Our know-how and expertise provide the answers to help with:

- Identifying defects early

- Prioritising remediation

- Minimising remedial costs

- Extending operating life

- Managing risk

- Protecting your reputation

- Avoiding environmental consequences

- Complying with legistation

- Addressing vulnerable areas

Well Integrity Services

Bond Quality

Channeling

Zonal Isolation

ID, OD, Thickness, identify pitting / holes / scale / etc

- Baseline Integrity & Drilling Wear Assessment

- 3D (modeling) & 4D (timelapse) Analysis

- BOP & Jewelry Condition Analysis

- Remedial Placement Location (plugs, straddles, patches, etc)

- Well Entry / Downhole Restriction Evaluation

- open

- closed

- partial

single and multi barrier annular leaks

Well Integrity Tools

Radial Bond Tool (RBT)

- Realtime & Memory Sondex BH

*Acoustic Borehole

- Imager Cement Mode (ABI-C)

- Realtime only

- Advanced Logic Technology

* Ultrasonic Cement Evaluation via a slim 1 11/16” OD Toolstring

Noise Tool (NTO) / small frequency range station stops – Realtime & Memory – Sondex BH

Leakpoint S100 / high frequency single barrier leaks – Realtime & Memory – Archer Owned

(partnership access)

VIVID / dual sensor broad frequency multi barrier leaks – Realtime & Memory – Archer Owned

(partnership access)

24 / 40 / 60 Multi-finger Caliper (MFC 24 / 40 / 60)

– Realtime & Memory – Sondex BH

80 Multi-finger Caliper (MFC80) – Realtime only – Sondex BH

High Pressure-High Temperature 40 Multi-finger Caliper (HPHT MFC40)

– Realtime & Memory – Sondex BH / READ upgraded

Extended Fingers (MFC-EXT) – for all MFC tools – increases casing measurement range

ZeroWear™ Fingers (ZW) – erosion resistant suitable for corrosive well environments & for all

MFC tool sizes

* Standard fingers are made with beryllium copper finger-tips that are coated with spray-on tungsten carbide

* READs Zerowear fingers replace standard spray on material with an infused tungsten metal matrix

Magnetic Thickness Tool (MTT) / single casing – Realtime &

Memory – Sondex BH

Magnetic Thickness Detector (MTD) / multi casing – Realtime &

Memory – GoWell (rental)

Magnetic Imaging Defectoscope (MID) / multi casing – Realtime &

Memory – Archer Owned (partnership access)

Downhole Video Camera – Realtime & Memory – EV Cameras Owned

(partnership access)

*Acoustic Borehole Imager – Integrity Mode (ABI-I) – Realtime only –

Advanced Logic Technology

* Ultrasonic Cement Evaluation via a slim 1 11/16” OD Toolstring

It’s easy to see why operators choose READ as their well integrity partner

We have three decades of experience and expertise in the energy industry. We can support you from dedicated facilities across the globe. Our highly-skilled field engineers can mobilise to any worldwide location at the shortest of notice. We deliver comprehensive and high-precision data analysis and interpretation. We have an impeccable safety track record.

In short, we deliver the ultimate all-encompassing well integrity service across the life-of-field.

Speak to us and find out how our well integrity services can help you improve the efficiency and reliability of your hydrocarbon recovery around the world.

QUICK LINKS

GET IN TOUCH

STAY CONNECTED

© 2023 READ Cased Hole Limited. All rights reserved.